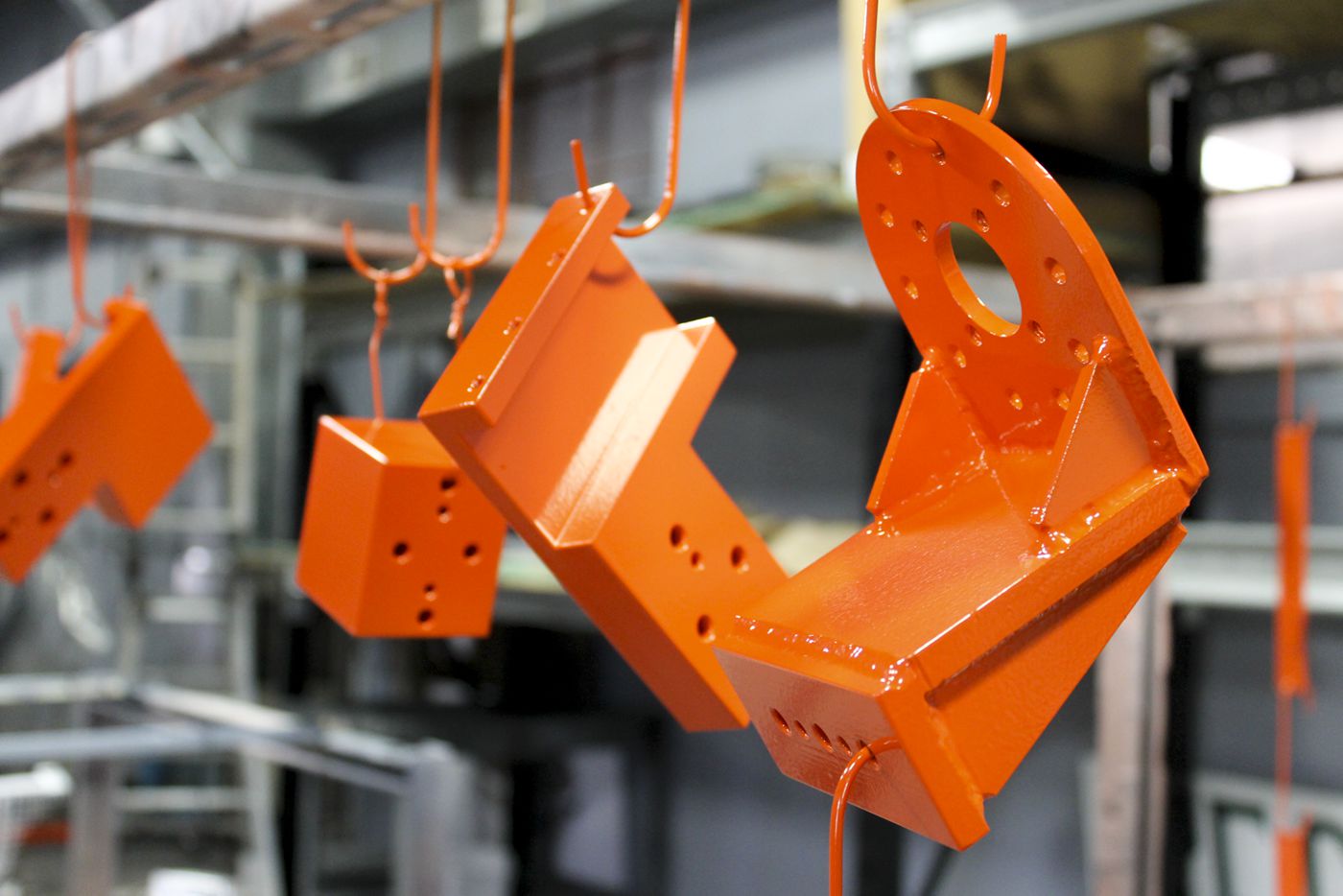

Powder Coating

Most shops will return flaws and defects in 40% of your product during the powder coating process. For some reason the industry has convinced itself that this is an acceptable rate of loss when powder coating. We do things a bit differently.

At Epic, product doesn’t leave the shop until it is right.

If your powder coating shop is estimating this 40% rejection rate, please talk to us! We would love to powder coat a sample of your piece for you, so you can see the quality of the work that we do.

Why powder coat?

Powder coatings produce amazingly durable finishes with dramatic advantage over wet paint in resistance to abrasion, corrosion, scratching, and chemicals. They stay bright with less fading, and color selection is virtually unlimited with high and low gloss, metallic, and clear finishes available. Texture selections range from smooth surfaces to wrinkled or matte finishes, and rough textures are available for hiding surface imperfections. Thick coatings can be achieved quickly and efficiently.

Powder coating contains no solvent, emitting negligible, if any, polluting VOCs into the atmosphere. The powder used for the process is a mixture of finely ground pigment and plastics. This mixture is sprayed onto the surface being coated, where it adheres electro-statically until heated and fused into a uniform coating in a curing oven. Powder coating can be applied to virtually any type of metal, and many other substrates, including glass and ceramic.